Our Products

From floor-mounted Servofill machines to complete packaging lines. Including design, project guidance, test facilities, installation and spare parts.Contact Us

Webb Automation offers a wide range of systems for packaging powders, granules, or particulate products into rigid and flexible containers. All our solutions guarantee careful handling and accurate portioning, to meet your specific filling requirements and the size, shape and form of container you need to fill.

Find out more about our solutions below!

Servo machines: designed for precision and efficiency in operations

Our Servo-Fill SF5 machines allow for precise control over a wide range of fill volumes, speeds, and other critical parameters. Augers of different sizes precisely measure and transport a wide range of bulk materials or powders through the filling machine, dispensing them into the packaging.

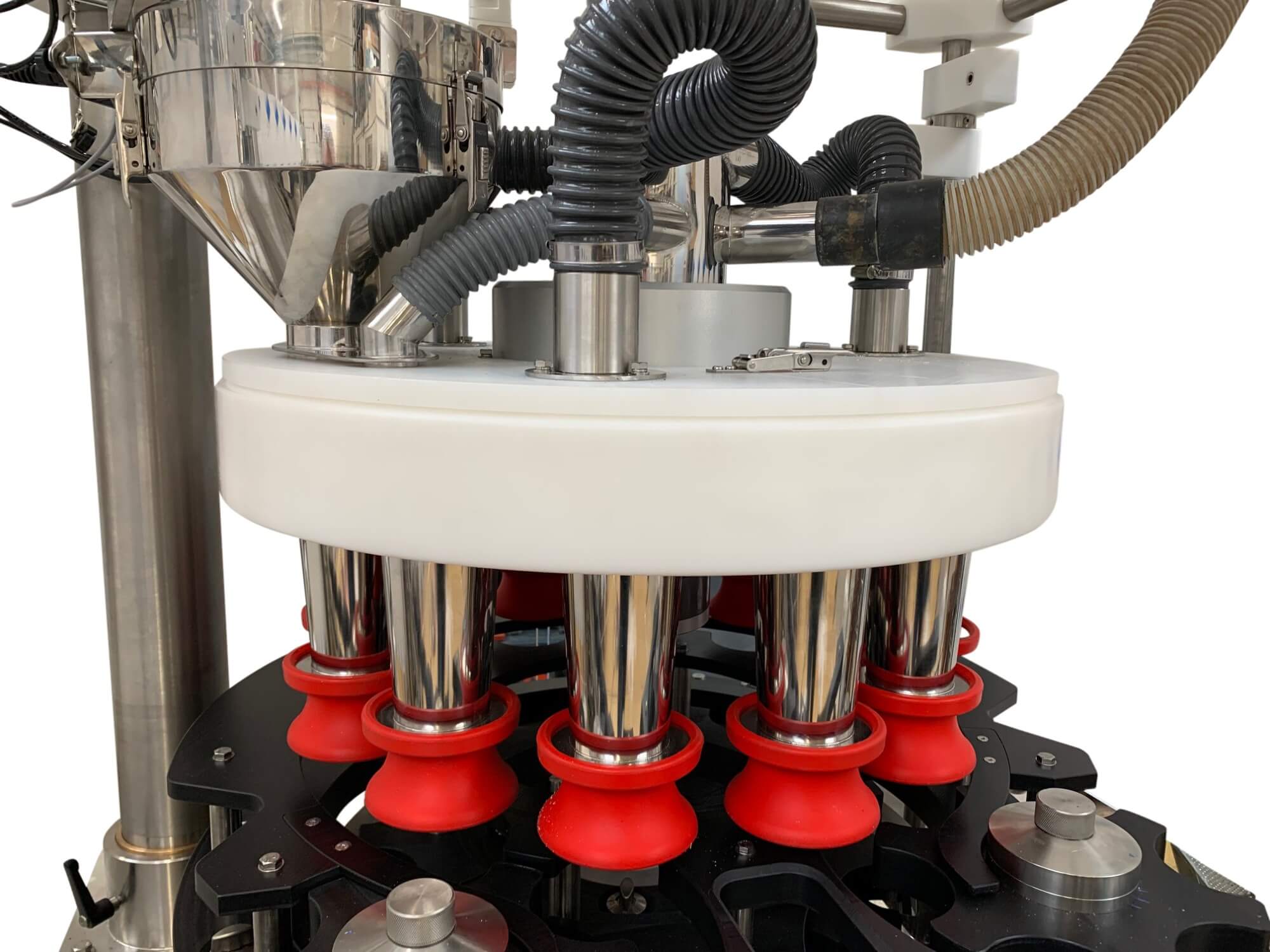

Rotary filling machines – continuous high-speed, extremely accurate filling

Our versatile rotary filling machines are designed for continuous high-speed, precise filling of various products, including powders and granules, into containers.

Line integration: versatile, high throughput integrated solutions with minimal manual intervention

Webb Automation's fully integrated In-line Conveyor Filling Lines are designed to provide efficient, automated filling solutions for a wide variety of products, particularly powder and granular products.

Webb Automation’s systems handle a wide range of products.

Powders

- Milk, Custard, Cocoa

- Toner, Carbon Black

- Grout, filler, plaster

- Icing Sugar, Table Salt

- Soup, Flavourings,

- Spice, Ground Coffee

- Cheese, Dry Syrup

- Penicillin, vitamin drinks

- Bouillabaisse

- High-fat content Bakery

Granules & Particulates

- Crystallised Sugar

- Dry Part Drink Formulations

- Rock Salt, Calcium Carbonate

- Coffee, Gravy

- Peppercorns, Plant food

- Leaf Herbs, Fish Flakes, Breadcrumbs

- Soup –Noodles & veg.

- Coffee Beans, Pulses

- Slug pellets